In today's health-conscious world, the demand for clean and pure drinking water is at an all-time high. This has led to the proliferation of mineral water bottling plants across the country, including in Mumbai. If you are considering setting up a mineral water bottling plant in Mumbai, look no further than Krupashindhu Consulting Engineers, your trusted partner for turnkey solutions in the field.

Krupashindhu Consulting Engineers is a renowned name in the industry, with over two decades of experience in designing, manufacturing, and installing mineral water bottling plants. Based in Mumbai, we have earned a reputation for delivering top-notch solutions that adhere to the highest industry standards.

Krupashindhu Consulting Engineers is a renowned name in the industry, with over two decades of experience in designing, manufacturing, and installing mineral water bottling plants. Based in Mumbai, we have earned a reputation for delivering top-notch solutions that adhere to the highest industry standards.

Expertise and Experience: With a team of seasoned professionals and engineers, we have successfully executed numerous projects in Mumbai and beyond. Our expertise in the field ensures that your project will be handled with precision and efficiency.

Customized Solutions: We understand that each client's requirements are unique. Therefore, we offer tailor-made solutions to meet your specific needs and budget. Whether it's a small-scale plant or a large production unit, we've got you covered.

Quality Assurance: Quality is at the heart of everything we do. Our state-of-the-art manufacturing facility ensures that all components and equipment used in your bottling plant are of the highest quality, meeting regulatory standards and industry best practices.

Cost-Effective: We believe in delivering value for money. Our cost-effective solutions are designed to maximize your return on investment while minimizing operational costs.

Timely Execution: We understand the importance of time in the business world. Our team is committed to delivering projects on time, ensuring minimal disruption to your business operations.

When it comes to setting up a Mineral Water Bottling Plant in Mumbai, Krupashindhu Consulting Engineers is the name you can trust. With our experience, expertise, and commitment to quality, we have become the preferred choice for businesses seeking reliable and cost-effective solutions in this industry. Contact us today to discuss your project requirements and take the first step towards providing clean and pure drinking water to the people of Mumbai.

The approximate quality of treated water is as follows considered for design of system.

| Suspended Solids | Nil |

| Turbidity | Nil |

| pH | 7.00 to 7.5 |

| T D S | Less than 40 ppm |

| Total Hardness | 30 ppm as CaCo3 |

| Bacteria Coliform | Nil |

The above water quality is approximate assumption, We can change property of minerals/ions in water by editing the raw water in R.O. treated water.

| Max. Temperature | 40 deg. C |

| Free Chlorine, Bacteria, Oil | Nil |

| Iron, Manganese.etc. | Nil |

| Turbidity | Less than 1.0 NTU |

| Type | Stretch Blow Molding, Extrusion Blow Molding, Injection Blow Molding |

| Mould Cavity | 1 cavity, 2 cavity, 3 cavity, 4 cavity |

| Automation Grade | Automatic |

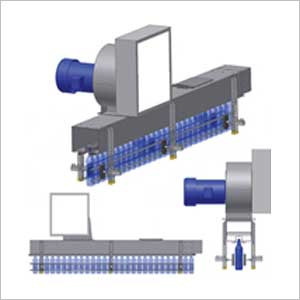

We are the manufacturers of Semi Auto Blow Moulding Machine.Semi Auto Blow Moulding Machines are engineered to perfectly match up with the specific working needs of different related industry sectors. Providing for optimum molding interface, these machines can also be availed in different technical specifications as per client’s requirement for PET Blowing. Further, these can be made available in different working capacities from 600, 1200 and 2000 bottles on per hour basis.

We are offering latest technology based PET blowing machines that are made available in different output capacities. These include :

Nominal Capacity (BPH) : 1500 @1000ML or (30 BPM)

Filling Speed (BPH)

200/300/500ml Bottle : 5400 (90BPM)

1500 ml BOTTLE: 2400 (40BPM)

2000ml: 1500 (25BPM)

Bottle Dia - Max / Min : 50mm/120mm

Rinser (Nos) : 8

Filling Valves (Nos) : 8

Capper (Nos) : 4

Overall Dimension (Mtrs)

Width : 1.5

Length : 2.0

Height : 2.8

Power :

Main Drive Motor 2.0 HP

Elevator Motor 0.5 HP

Water to Filler Pump 2.0 HP – Client Supply.

Rinser Drained water Pump 1.0 HP- Client Supply.

Compressed Air :

C.F.M. at 100 PSI : 6-8

Compressor H.P. : 7.5

Water Consumption (Rinser) : 700 Litres/Hrs.

The machine will have 8 washing nozzles working under positive pump pressure of de-mineralized water. The machine does not include centrifugal pump for demineralized water. You would be required to supply water at about 1.5 KG at a rate of 700 liters per hour. The bottles from the conveyor will be taken by the neck starwheel and neck guide and will transfer to the Rinser gripper finger. The gripping fingers will hold the bottles by neck and necessary guide bars will invert the bottle up side down by 180 degree. The duly inverted bottles will receive water from the washing nozzles on rear of the machine. The washing and draining will operate from 90o to 270o rotation of the washing machine. Zero degree position is in front of the operator. In 180o rotation the washing cycles will be stopped and from 180o to 270o the draining will take place. The bottles will be re-inverted and delivered through neck star wheel and neck guide to the filling machine. The drained water can be accumulated and allowed to drain in the tank and recycling after re-processing (if required).The machine will be fully constructed in stainless steel above the table top level. The bottle handling parts will be of nylon. The appropriate guards will be provided to prevent water splashing.

Tank :

Small Cylindrical type stainless steel tank is machined to close tolerance and mirror finished. The corners are generously rounded off so as to facilitate sanitizing with detergent and steam.

Filling Heads: (Air separate type) :

The filling heads are of simple sanitary design with Air separate type, all metal parts of stainless steel 316, non-metallic components of tasteless, odorless, non-toxic, food quality rubber and nylon. Complete valve can be removed from filler tank without opening the lid cover.

Lift Cylinder System :

Lift cylinders are made of stainless steel while stationery pistons guide bushes are made of delrin. The bottle neck platforms are shaped stainless steel to hold the bottle correctly at all times. The controlling cam is steel hardened to resist wear.

Bottle Handling :

Bottle are handled by positive neck spider and neck guide throughout the machine with minimum change parts required is Infeed and Outfeed Spider and Guide for each size of bottle. There are no height adjustments required for different sizes of bottles.

Table Top :

Complete table top covered with stainless steel sheets.

Lubrication :

All vital points lubricated through centralized pneumatic system connected to automatic high pressure cycle, for grease as well as oil.

The capping system shall have PICK & PLACE type of cap delivery and chucks shall be of latest design MAGNETIC slip clutch type. Cap delivery hopper is rotary type. Cap elevator from floor level can be supplied at extra cost. The bottle will enter the capping turret and by adjustable torque chucks, cap will be firmly tightened. Duly capped bottles will be transferred on the conveyor.

In the complete machine bottle will be running by neck.

|

Sr. No. |

Name of Equipment |

Range |

Qty |

|

1 |

Hot Air Oven Digital Controlled With Thermometer Sr. No : KCE 001 Make : Labline |

50 to 2200 C |

1 No |

|

2 |

Water Bath Digital Controlled With Thermometer Sr. No : KCE 002 Make : Labline |

Room Temp to 950 C |

1 No |

|

3 |

Hot Plate Digital Controlled Sr. No : KCE 003 Make : Labline |

0 to 2500C |

1 No |

|

4 |

Gas Stripping Apparatus With Flow Pump & Flow Meter

|

0 to 100 LPH L.C. 5 LPH |

1 No |

|

5 |

Ph Meter Make : Labline |

0 to 14 PH L.C. 0.01 PH |

1 No |

|

6 |

Turbidity Meter Make : Labline |

0 to 1000 NTU L.C. 0.1 NTU |

1 No

|

|

7 |

Distillation Unit Make : Labline |

4 Liter |

1 No

|

|

8 |

Digital Spectrophotmeter With 10mm & 50mm Cell Make : Labline |

340 to 960 nm L.C. 1 nm |

1 No

|

|

9 |

Single Pan Balance Sr. No : KCE 004 Make : Labline |

0 to 200 gm L.C. 0.1 mg |

1 No |

|

10 |

Magnetic Stirrer With Hot Plant Digital Controlled With Thermometer Sr. No. KCE 005 Make : Labline |

|

1 No |

|

11 |

Bacteriological Incubator Digital Controlled With Thermometer Sr. No : KCE 006 Make : Labline |

Ambient to 1100 C L.C. 0.10C |

1 No

|

|

12 |

B.O.D. Incubator With Digital Display Of Temp (200C) Sr. No. KCE 007 Make : Labline

|

0 to 600C L.C. 0.10C |

1 No |

|

13 |

B.O.D. Incubator With Digital Display Of Temp (250C) Sr. No : KCE 007 Make : Labline |

0 to 600 C L.C. 0.10 C |

1 No |

|

14 |

Centrifuge Make : Labline |

4 Tube UP to 3500 RPM |

1 No |

|

15 |

Microscope Make : Labline |

10X, 45X |

1 No |

|

16 |

Colony Counter Make : Labline |

0 to 999 |

1 No |

|

17 |

Laminar Ari Flow |

- |

1 No |

|

18 |

Autoclave Sr. No : KCE 008 |

0 to 2.1 kg/Cm2 0.005 kg/cm2 |

1 No |

|

19 |

Filtration Assembly With Vacuum Pump For Microbiology |

|

1 No |

|

20 |

Dial Thickness Gauge Make : Labline

|

0 to 1 mm L.C. 0.001 mm |

1 No

|

|

21 |

Wooden Block Make : Labline |

120 N |

1 No

|

|

22 |

Scale |

0 to 60 mm L.C. 1 mm |

1 No |

|

23 |

Fuming Hood |

|

1 No |

|

24 |

Thermameter Make : Labline Sr. No : KCE 009 |

Range (0 to 360)deg L.C. 1 deg |

1 No |

|

25 |

Thermameter Make : Labline Sr. No : KCE 010 |

Range (0 to 360) deg L.C. 1 deg |

1 No |

|

Sr. |

List of CHEMICALS |

Rage |

Quantity

|

|

1 |

1,10 Phenanthroline Monohydrate |

5 gm |

1 |

|

2 |

Acetic Acid Glacial |

500 ml |

1 |

|

3 |

Activated Cabone |

500 gm |

1 |

|

4 |

Aluminium Potassium Sulphate |

500 gm |

1 |

|

5 |

Ammonia Solution |

500 gm |

1 |

|

6 |

Ammoniaum Ferrous Sulphate |

500 gm |

1 |

|

7 |

Ammoniaum Acetate |

500 gm |

1 |

|

8 |

Ammonium Chloride |

500 gm |

1 |

|

9 |

Ammonium Dichromate |

100 gm |

1 |

|

10 |

Ammonium Hydraxide |

500 gm |

1 |

|

11 |

Antimony Metal |

25 gm |

1 |

|

12 |

Ascorbic Acid |

100 ml |

1 |

|

13 |

Barium Chloride (Dihydrate) |

500 gm |

1 |

|

14 |

Boric Acid Powder |

100 gm |

1 |

|

15 |

Bromocresol Green |

5 gm |

1 |

|

16 |

Buffer Tablet 4ph |

10 Tab |

1 |

|

17 |

BufferTablet 7ph |

10 Tab |

1 |

|

18 |

Buffer Tablet 9.2ph |

10 Tab |

1 |

|

19 |

Calcium Carbonate |

500 gm |

1 |

|

20 |

Calaium Hydroxide |

500 gm |

1 |

|

21 |

Cholring Solution (Hypochloride) |

500 gm |

1 |

|

22 |

Chloroform |

100ml |

1 |

|

23 |

Chromotropic Acid Crystal |

5 gm |

1 |

|

24 |

Cobaltous Chkirude Crystline |

100 gm |

1 |

|

25 |

Conc. HCL |

500 ml |

1 |

|

26 |

Conc. HNO3 |

500 ml |

1 |

|

27 |

Conc. Sulphuric Aciid |

500 ml |

1 |

|

28 |

Copper Metel Powder |

50 gm |

1 |

|

29 |

Cyclohexanone |

500 ml |

1 |

|

30 |

Di (2-Ethyl Hexyl) Sulphosuccinate |

100 gm |

1 |

|

31 |

Di Isopropy ether |

100 ml |

1 |

|

32 |

Di Sodium EDTA |

100 gm |

1 |

|

33 |

Diammonium Hydrogen Phosphate |

500 gm |

1 |

|

34 |

Diethylene Gllycol Monobuty ether |

100 ml |

1 |

|

35 |

Dipotassium Hydrogen Phosphate |

500 gm |

1 |

|

36 |

Dodecylbenzene Sulphonic Acid |

10gm |

1 |

|

37 |

EDTA |

100 gm |

1 |

|

38 |

Erochrome Black T |

25 gm |

1 |

|

39 |

Eriochrome Cyanine –R- Dye |

10 gm |

1 |

|

40 |

Ethanol |

500ml |

1 |

|

41 |

Ethyl Acetate |

500 ml |

1 |

|

42 |

Ethylene Glycol |

500 gm |

1 |

|

43 |

Ferric Chloride |

500 gm |

1 |

|

44 |

Ferric Cirtrate |

500 gm |

1 |

|

45 |

Gelatin Purified |

100 gm |

1 |

|

46 |

Gllycerol |

100 ml |

1 |

|

47 |

Hexa Methyklene Tetramine (Hexamine) |

500 gm |

1 |

|

48 |

Hydrazine Sulphate |

100 gm |

1 |

|

49 |

Hydrogen Peroxide |

500 ml |

1 |

|

50 |

Hydroxyl Amine Hydrochloride |

100 gm |

1 |

|

51 |

Isopropyl Alcohol |

500 ml |

1 |

|

52 |

Manganese Sulphate |

100 gm |

1 |

|

53 |

Mercuric Chloride |

25 gm |

1 |

|

54 |

Methanol |

500 ml |

1 |

|

55 |

Methyl orange |

25 gm |

1 |

|

56 |

Meethyl Red indicator |

25 gm |

1 |

|

57 |

Methylene Blue |

25 gm |

1 |

|

58 |

Murexide |

25 gm |

1 |

|

59 |

NED Dihydro Chloride |

5 gm |

1 |

|

60 |

Neocuproine |

1 gm |

1 |

|

61 |

N-N Dimethyl _P –Phenyline Oxalate |

5 gm |

1 |

|

62 |

Ortho –Toluidine Di hydrochloride |

25gm |

1 |

|

63 |

Patton & Reader’s Indicator |

5 gm |

1 |

|

64 |

Phosphoric Cynide |

125 ml |

1 |

|

65 |

Phosphoric Acid |

500 gm |

1 |

|

66 |

Potassium Cynide |

100 gm |

1 |

|

67 |

Poassium Chloride |

500 gm |

1 |

|

68 |

Potassium Chloroplatinate |

1 gm |

1 |

|

69 |

Potassium Chromate |

100 gm |

1 |

|

70 |

Potassium Dihydropltinate |

500 gm |

1 |

|

71 |

Potassium Iodide |

100 gm |

1 |

|

72 |

Potassium Nitrate |

500gm |

1 |

|

73 |

Potassium Periodate |

100 gm |

1 |

|

74 |

Potassium Permanganate |

100 gm |

1 |

|

75 |

Potassium Dichromate |

100 gm |

1 |

|

76 |

Silver Nitrate Solid |

5 gm |

1 |

|

77 |

Sidium Acetate |

500 gm |

1 |

|

78 |

Sodium Arsebite |

25 gm |

1 |

|

79 |

Sodium Ascorbate |

100 gm |

1 |

|

80 |

Sodium Carbanate a Anhydrous |

500 gm |

1 |

|

81 |

Sodium Chloride |

500 gm |

1 |

|

82 |

Sodium Citrate |

100 gm |

1 |

|

83 |

Sodium Hydrogen Carbonate |

500 gm |

1 |

|

84 |

Sodium Hydroxide |

500 gm |

1 |

|

85 |

Sodium Nitrie |

500 gm |

1 |

|

86 |

Sodium Oxala |

500 gm |

1 |

|

87 |

Sodium Sulphate Anhydrous |

500 gm |

1 |

|

88 |

Sodium Sulphite |

500 gm |

1 |

|

89 |

Sodium Thiosulphate |

500 gm |

1 |

|

90 |

Starch Soluble |

50 gm |

1 |

|

91 |

Sulphanilamide Reagent |

25 gm |

1 |

|

92 |

Sulphurous acid N/50/Sulphar dioxide |

100 ml |

1 |

|

93 |

Triethanolamine |

500 ml |

1 |

|

94 |

Urea |

500 gm |

1 |

|

95 |

Zinc Granuals |

100 gm |

1 |

|

96 |

Zinc Sulphate |

500 gm |

1 |

|

97 |

Zincon |

1 gm |

1 |

|

98 |

Zinc Acetate |

500 gm |

1 |

|

|

|

|

|

Sr. |

Description |

Quantity |

|

1 |

Aspargine Proline Broth |

100 gm |

|

2 |

Chlormphenicol Yeast Extract Dextrose Agar |

100 gm |

|

3 |

Differential Reinforced Clostridia Medium |

100 gm |

|

4 |

Plate Count Agar |

100 gm |

|

5 |

Brilliant Count Agar |

100 gm |

|

6 |

MacConkey’s Broth |

100 gm |

|

7 |

MacConkey’s Agar |

100 gm |

|

8 |

Milk Agar With Cetrimide (Twin) |

100 gm |

|

9 |

Nutrient Broth |

100 gm |

|

10 |

Nutrient Agar |

100 gm |

|

11 |

Simmon’s Citrate Agar |

100 gm |

|

12 |

Peptone Water |

100 gm |

|

13 |

MR-VP Medium |

100 gm |

|

14 |

Grams Staining Kit |

1 Pkt |

|

15 |

Tryptone Soy Agar |

100 gm |

|

16 |

Tryptophan Broth |

100 gm |

|

17 |

Oxidase Reagent |

100 gm |

|

18 |

Kovac’s Reagent |

100 gm |

|

19 |

Tryptone Bile Agar |

100 gm |

|

20 |

T.T.C. Solution |

0.10 gm |

|

21 |

Tergitol-7 |

100 gm |

|

22 |

Lactose TTC |

100 gm |

|

23 |

Indole Reagent |

10 gm |

|

Sr. |

Description |

Specification |

Quantity

|

|

1 |

Nesseler Cylinder |

50 ml |

5 No. |

|

2 |

Volumetric Flask |

10 ml |

4 No. |

|

50 ml |

4 No. |

||

|

100 ml |

4 No. |

||

|

250 ml |

2 No. |

||

|

500 ml |

2 No. |

||

|

1000 ml |

1 No. |

||

|

3 |

Graduated Pipette |

1 ml |

1 No. |

|

5 ml |

1 No. |

||

|

10 ml |

1 No. |

||

|

25 ml |

1 No. |

||

|

4 |

Separating Funnel |

125 ml |

1 No. |

|

500 ml |

1 No. |

||

|

5 |

Conical Flask |

250 ml |

4 No. |

|

500 ml |

2 No. |

||

|

6 |

Beaker |

50 ml |

3 No. |

|

100 ml |

3 No. |

||

|

250 ml |

3 No. |

||

|

500 ml |

3 No. |

||

|

7 |

Petri Dish |

……. |

20 Pair |

|

8 |

Glass Slide |

……. |

1 Pkt |

|

9 |

Wide Mouth Bottle |

1000 ml |

1 No. |

|

10 |

Measuring Cylinder |

50 ml |

2 No. |

|

100 ml |

2 No. |

||

|

11 |

Screw Cap Bottle |

100 ml |

4 No. |

|

12 |

Iodine Flask |

250 ml |

1 No. |

|

13 |

Whatman Filter Paper |

No. 40 |

1 Pkt |

|

14 |

Pipette Stand |

……. |

1 No. |

|

15 |

Burette Stand |

…… |

1 No. |

|

16 |

Carbon Column Stand |

|

1 No. |

|

17 |

Spechula |

……. |

1 No. |

|

18 |

Wash Bottle |

250 ml |

2 No. |

|

19 |

Evaporating Dish (Silica Dish) |

30 ml |

1 No. |

|

20 |

Durham’s Tube |

|

1 Pkt |

|

21 |

Test Tube |

20 ml |

10 No. |

|

22 |

Test Tube Stand Vertical |

|

1 No. |

|

23 |

Test Tube Holder |

|

1 No. |

|

24 |

Dropper |

……… |

2 No. |

|

25 |

Glass Rod |

……… |

2 No |

|

26 |

Flask tong |

……… |

1 No |

|

27 |

Burner with stop cocke |

………. |

1 No. |

|

28 |

With Loop With Holder |

………. |

1 No. |

|

29 |

Pipette Bulb |

Small |

1 No. |

|

30 |

Pipette Bulb |

Medium |

1 No. |

|

31 |

Tissue Paoer |

………. |

1 Roll |

|

32 |

Cotton |

……… |

1 Roll |

|

33 |

Carbon Column |

……… |

1 No |

|

34 |

Filtration Flask (1Lit) |

1000 ml |

1 No |

|

35 |

Beaker (Plasti) |

50 ml |

2 No |

|

|

|

100 ml |

2 no |

|

250 ml |

2 no. |

||

|

500 ml |

2 no. |

||

|

250 ml |

2 no. |

||

|

36 |

Reagent Bottle (Plastic) |

250 ml |

24 no. |

|

500 ml |

12 no. |

||

|

37 |

Desiccators |

|

1 no. |

|

38 |

Themometer (-10 to 110c) |

|

01 Packet |

|

39 |

Themometer (-10 to 110c) |

|

01 Packet |

|

40 |

Themometer (-10 to 110c) |

|

01 Packet |